The addition of cnfs to the ceramic matrix caused a slight deterioration of the mechanical properties of the composite but its electrical conductivity improved significantly.

Improve the mechanical properties of ceramic matrix composites.

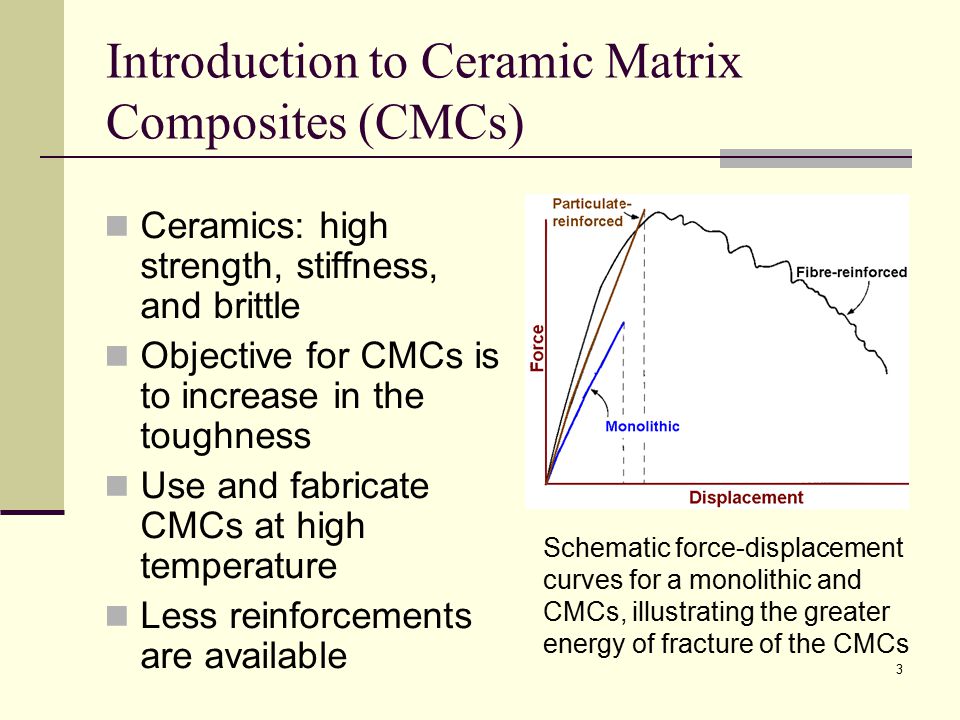

Ceramic matrix composites cmcs generally consist of ceramic fibers or whiskers in a ceramic matrix.

More particularly sic nanoparticles have been introduced in cmcs to enhance the mechanical and thermal properties of ceramic materials such as al 2 o 3 and mullite.

High strength at elevated temperature high hardness good corrosion and erosion behaviour high elastic modulus low density and generally low coefficients of friction that make them potential candidates for many structural applications.

Mechanical properties of fiber reinforced composites depend on a properties of constituents b interface strength c fiber length orientation and volume fraction d all the above 10.

Common properties of ceramic matrix composites are 3.

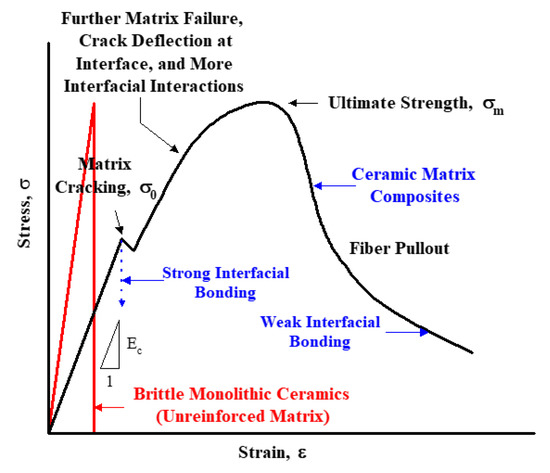

These drawbacks are addressed by the use of fibre reinforcement in ceramic matrix composites.

Advanced ceramics exhibit a combination of properties.

Ils were used to disperse mwcnts and catalyze the ring opening of epoxy groups of ema gma to improve interfacial tension and adhesion.

This was related to the modification of grain boundaries as a result of the introduction of cnfs into the zirconia matrix.

High thermal shock and creep resistance.

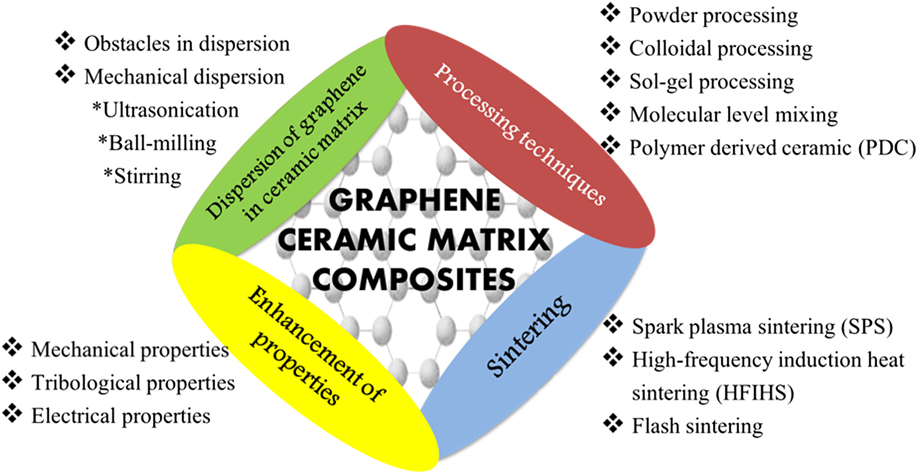

Graphene addition is an effective way to elevate the mechanical properties of composite ceramics especially with respect to toughness.

For graphene al 2 o 3 composite ceramics the 28 33 and 53 increase in fracture toughness values were reported for the composites filled with 0 8 vol 0 22 wt and 2 0 wt graphene.

In addition the graphene addition also plays an important role in the electrical properties of composite ceramics.

The reinforcements used in ceramic matrix composites cmc serve to enhance the fracture toughness of the combined material system while still taking advantage of the inherent high strength and young s modulus of the ceramic matrix.

Cmcs are designed to overcome the main drawback of monolithic ceramics namely their brittleness.

In this study ema gma as epoxy containing elastomer was used to improve mechanical properties of pla.

Naslain mr pomeroy in reference module in materials science and materials engineering 2016.

Al alloys for engine automobile parts are reinforced to increase their a strength b wear resistance c elastic modulus d density 9.

Mwcnts as conductive fillers were used to improve the dielectric properties of pla composites.