The spray kit comes with up to 650 feet of foam and comes with a gun dispenser and hose assembly wrench petroleum jelly packet and operation instruction manual.

Ideal temperature to spray foam insulation.

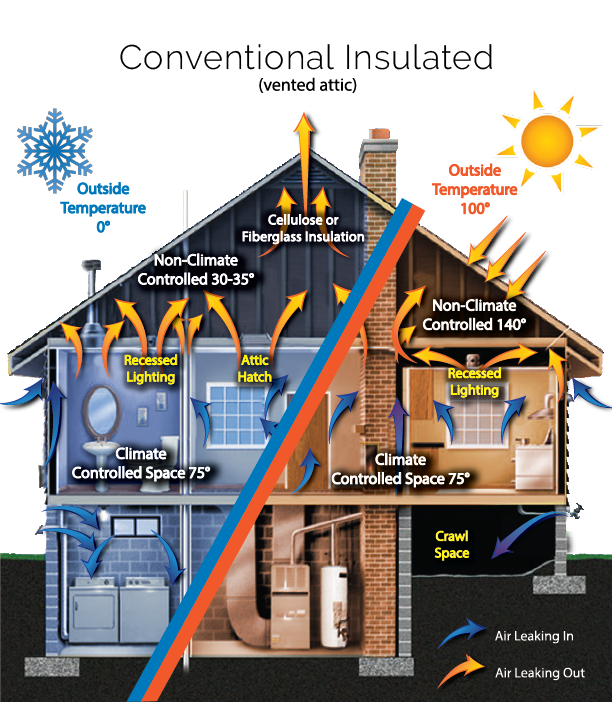

Given that both insulators are equal in r value the difference in thermal resistance relies heavily on proper installation and air sealing.

The touch n seal diy foam insulation kit is spray foam kit that uses diy foam for insulation.

This spray is designed in such a way it keeps the house warmer in winter and cool in summer.

Half pound 0 23 kg spray foam is the most cost effective and therefore most popular spray foam insulation.

Although spray foam insulation has been in use since the 1940s primarily for aircraft for the past 30 years continual product innovation has seen the increased adoption of spray foam insulation in residential and commercial construction.

This spray foam insulation kit will help fill any cavities cracks along with expansion joints for insulation and air sealing.

I can also tell you that 73 of all statistics are made up on the spot so please don t ask for.

Touch n foam 2 component spray foam expands and touch n foam 2 component spray foam expands and cures quickly to fill cavities gaps cracks expansion joints and other sources of air leakage in a building envelope.

The rapid growth of sprayed foam insulation in building construction thanks in part to its immediate and long term.

In the wintertime the closer they are to 80 degrees without going over the better.

Spray foam insulation is a great product.

This is also a multifunctional kit that can be used for reducing the temperature of the houses.

If the test patch properly adheres then carry on.

It has an r value between 2 and 3 5 making it about as dense as dormant air.

Homes insulated with it can be some of the most efficient and comfortable homes built.

Dow froth pak 650 4 spray foam insulation kits class a fire rated closed cell foam covers 2600 sq ft 4 7 out of 5 stars 9 2 909 23 2 909.

The r value of cellulose insulation ranges from 3 6 3 8 per inch and spray foam insulation ranges from 3 5 3 7 per inch of insulation.

In essence by spraying this thin preliminary layer of foam you are creating an environment that is the perfect temperature for spray foam to cure.

Resists moisture that can lead to mold or mildew and provides increased sound and thermal insulation.

This is the recommendation of idi s insulation experts but always check your tech data sheet for specifics.

The minimum temperature for storing spray foam insulation is 70 degrees but the drums should ideally be stored between 70 and 80 degrees.

A closeup of spray foam insulation.

It helps stop energy loss and can insulate stud wall cavities up to two inches thick.